To make an engine start it must be turned at some speed, so that it sucks fuel and air into the cylinders , and compresses it.

The powerful electric starter motor does the turning. Its shaft carries a small pinion ( gear wheel) which engages with a large gear ring around the rim of the engine flywheel.

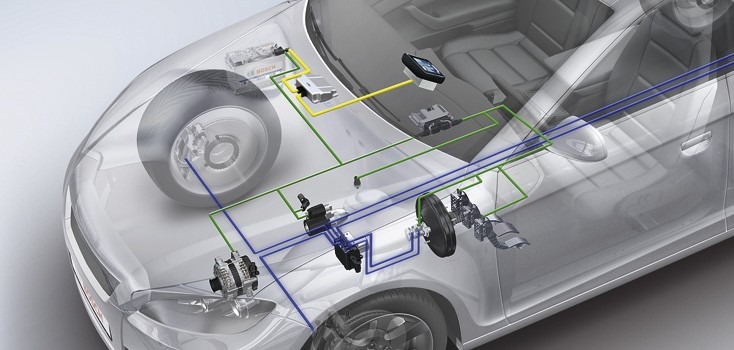

In a front-engine layout, the starter is mounted low down near the back of the engine.

The starter needs a heavy electric current, which it draws through thick wires from the battery . No ordinary hand-operated switch could switch it on: it needs a large switch to handle the high current.

The switch has to be turned on and off very quickly to avoid dangerous, damaging sparking. So a solenoid is used – an arrangement where a small switch turns on an electromagnet to complete the circuit .

The starter switch is usually worked by the ignition key. Turn the key beyond the ‘ignition on’ position to feed current to the solenoid.

The ignition switch has a return spring, so that as soon as you release the key it springs back and turns the starter switch off.

When the switch feeds current to the solenoid, the electromagnet attracts an iron rod.

The movement of the rod closes two heavy contacts, completing the circuit from the battery to the starter.

The rod also has a return spring -when the ignition switch stops feeding current to the solenoid, the contacts open and the starter motor stops.

The starter motor itself has a device, called a Bendix gear, which engages its pinion with the gear ring on the flywheel only while the starter is turning the engine. It disengages as soon as the engine picks up speed, and there are two ways by which it does so – the inertia system and the pre-engaged system.

The inertia starter relies on the inertia of the pinion – that is, its reluctance to begin to turn.